Guose has always been customer-focused, as the core concept of gas station construction

In the competitive environment of quality, measurement, service and price, whether the design and construction of the gas station meets the needs of the target customers and whether it is sufficient for the customers will play a very important role in the sales of the gas station.

First, the design concept of modern gas stationsAccording to relevant experts, in terms of gas station construction, China is at least 20 years behind developed countries such as the United States and Britain. Faced with this gap, advocating advanced design concepts, practicing first-class station building standards, and selecting advanced equipment and facilities will be the only way to improve the overall level and competitiveness of China's gas station industry.

1. Advocate advanced design concepts

(1) Before the design and construction of the gas station, the target customers should be investigated to analyze the consumer psychology and needs of the target customers. From every detail of design and construction, the concept of “customer first” is built.

(2) The size of the gas station depends on the analysis results of the business circle (vehicle flow, traffic flow structure, peak traffic period), depending on the real needs of the target customers.

(3) The layout of the gas station should avoid the intersection of vehicles and facilitate the entry and exit of customers as the first principle, and minimize the traffic jams in the station and the walking distance when the customer pays.

(4) Minimize the non-business area such as dormitory and office, maximize the business area such as lanes and parking lots, expand service functions and business projects, and achieve “one-stop consumption” as much as possible.

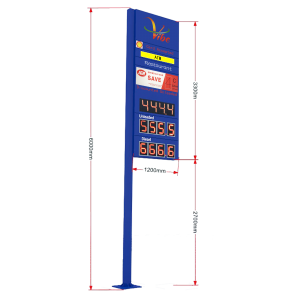

(4) The use of a distinctive CI image design highlights the visual impact and appeal of the gas station's appearance to the customer. Signs and price cards are especially important.

2. Standardization is an inevitable choice for the design and construction of gas stations

The unified image recognition system is the premise and basis for realizing the chain operation of gas stations. A set of mature, advanced and operational "Visual Image Recognition Manual", "Design Manual" and "Construction Standards" have the chain management of gas stations. Significance.

The standardization of gas station construction is definitely not the simplification of the construction scale and the layout of the station. It is based on the characteristics of the region, and the appearance and image are consistent, the main equipment models are consistent, and the service facilities are consistent, so as to obtain the unity of the overall construction style and image. Just like the KFC and McDonald's chain stores.

3. Emphasis on social responsibility based on "health, safety and environmental protection"

Gas stations are the window of oil companies, and the social responsibility of oil companies will be more reflected in gas stations. “Creating harmony between energy and the environment” should be the sacred mission of every gas station.

Applying new technologies, we will gradually promote and popularize self-service fuel dispensers and cash register systems, POS machines, tank level measuring instruments, oil and gas recovery devices, camera monitoring devices, automatic sprinkler foam fire extinguishing systems and other advanced equipment. Make fueling faster, healthier, safer and more environmentally friendly.

Second, the main steps and points of the gas station design

The gas station design includes four major steps: scale prediction, functional planning, layout and construction design.

Scale prediction

According to the “RES location score” results of the gas station, location type (city center station, suburban combined station, main road station, secondary road station, remote rural station) and expected daily sales, peak fueling demand, oil sales Parameters such as structure determine the size of the gas station. The design index for refueling scale includes:

(1) The size and shape of the red line used;

(2) Number and spacing of lanes, size and shape of the fuel shed;

(3) The number of refueling islands, the number of tankers (guns), sales varieties and their layout;

(4) the number and capacity of tanks;

(5) The width of the entrance and exit, the radius of the turn, etc.

2. Functional planning

According to the location type of the gas station, road conditions, traffic flow, surrounding environment, competitors and other factors, determine the target customer group of the gas station, analyze the consumer psychology and consumer demand of the main target customer group, and use this to carry out the service function planning of the gas station. . Determine whether to build a single gas station, or build a combination of "gas station + convenience store", "gas station + car service", "gas station + fast food".

3. Plane layout

Whether the design of the gas station is reasonable or not depends on whether the design plan and the layout of the building are convenient for the customer and whether it is beneficial to the operation. The general plan layout is the basis and core of the gas station design, and it is also the focus and difficulty of the gas station design. The general layout plan is mainly determined by the target customers of the gas station, the scale prediction, the service function positioning, and the land area.

4. Construction design

The construction design of the gas station includes: architectural design, process design, fire protection design, environmental protection design, selection of major equipment and facilities, and other auxiliary design. Gas station design is a highly professional job, and national regulations, industry standards and corporate rules are relatively sound, so this book is only a general discussion, does not involve technical details in the design and construction of gas stations.

Third, the gas station's architectural design

The proper shape and façade of the building can make the building have a distinct "personality", which makes people feel refreshed and enjoys the beauty. On the contrary, the mediocre, monotonous and boring architectural image is often confusing, irritating and uneasy.

The gas station has a small volume, but it has a complementary effect with other buildings. In the architectural space, sometimes it is more direct and moving than tall buildings. Therefore, the design of the gas station should pay attention to innovation and organic integration with the built environment.

Fourth, the environmental greening of gas stations

What are the benefits of greening at gas stations, and why should the greening of the gas station be greened? Before answering this question, we must first understand the necessity and importance of urban greening.

Gas stations are generally located in the main roads, the location is conspicuous, very eye-catching, greening well, can beautify the streetscape, coordinate the environment, it is an integral part of urban greening. The greening of gas stations mainly has the following advantages:

1 Greening can improve the environment. The greening of gas stations, especially trees and lawns, plays an important role in easing the temperature rise and overcoming the heat of reflection. According to the measurement, reasonable greening can reduce the temperature in summer by 3-5 °C and the temperature in winter by 1-2 °C.

2 Greening can increase air humidity, create fresh air, and purify the atmosphere.

3 greening can prevent wind and sand. Reduce impurities in the air and reduce dust content.

4 Greening can reduce noise, plant trees in the city and open up green spaces, which has the effect of reducing noise.

5 Greening has disaster prevention and shock absorption. Once a fire or explosion accident occurs at a gas station, the green space can block the spread of fire. Many green plants can prevent the fire from spreading due to the large amount of water in the branches and leaves, and the isolation sparks are scattered.

After the greening of the gas station, it plays an important role in regulating the customer's mood, protecting vision and promoting health. At the same time, it also adds color to the overall greening of the city.

In addition, the gas station should be designed with appropriate open space, and some landscapes should be arranged to coordinate with the surrounding environment and buildings to make the design innovative.

Gas station greening should not affect the fueling business and equipment maintenance. At the entrance and exit of the petrol station, high school shrubs should not be planted so as not to affect the driver's sight and hinder the passage of the vehicle.

V. Gas station size and process calculation

The equipment and storage capacity of the gas station is mainly determined by the flow of the car. When the traffic volume is checked, the type of the vehicle and the type of oil required should also be investigated to determine the proportion of gasoline and diesel supplied to the gas station. The fueling capacity of a gas station depends mainly on the number of fueling lanes, the number of tankers, the tank capacity and the number of tanks.

For example, the traffic volume of the gas station is mainly based on small cars. The design is based on the sale of gasoline, and the diesel is properly placed. The ratio of gasoline to diesel is 2:1. If the traffic volume is investigated, the large container truck Mainly for people and trucks, the design is based on the sale of diesel, supplemented by gasoline, and the ratio of diesel to gasoline is 2:1. After determining the type of oil sold, determine the number of tankers, the number of fueling lanes, and the tank capacity.

1. Calculation of the number of tankers

The design capability of a gas station is directly related to the performance and configuration of the tanker. The general first-class gas station is equipped with 6-8 tankers, the second-level gas station is equipped with 3-5 tankers, and the third-level gas station is equipped with at least 2 tankers. The average daily fueling capacity of each tanker is 6000-10000L/(day. Taiwan), the domestic fuel dispenser takes a low fueling amount, and the imported fuel dispenser takes a high fueling amount. The refueling capacity is not only related to the number of tankers and performance, but also related to factors such as fueling lanes, vehicle flow changes, vehicle conditions, and gas station operation and management levels. Therefore, the determination of the gas station capacity is a complex problem with multiple factors. According to practice, the maximum fueling capacity of each tanker at a gas station is about 50% of its rated maximum flow. The number of gas station tankers can be calculated according to the following formula:

n=[(1000G)/(300Q)]β (2-1)

In the formula n-the number of tankers;

G-gas station annual fueling amount;

Q-average daily refueling amount of each tanker, take 6000-10000L/D. Taiwan; general 24h fueling service take 10000L/D. Taiwan; day service gas station take 8000L/D.

The utilization coefficient of the β-fuel dispenser is 1 for diesel and 2 for gasoline.

The setting of the tanker should take into account the different types of fueling of gasoline and diesel. At the same time, the maintenance and maintenance of the equipment should be considered to ensure the uninterrupted operation of the gas station.

2. The number of refueling lanes is determined

The size of the refueling capacity is directly related to the number of refueling lanes. There are many refueling lanes in the gas station, and there are more refueling times per unit time, and the refueling capacity is also large; there are fewer refueling lanes, and fewer refueling trains per unit time, so the refueling capacity is small. Generally, the first-class gas station has 4-6 lanes; the second-level gas station has 2-4 lanes; the third-level gas station usually has 1-2 lanes. Generally, the single lane width should not be less than 3.5m, the double lane width should not be less than 6.5m, and the main lane of the incoming and outgoing gas stations should not be less than 10m.

3. Determination of the capacity of the underground storage tank

When determining the underground tank capacity of a gas station, the distance between the gas station and the oil depot should first be considered. If the distance is far, the capacity of the underground storage tank can be larger, and vice versa. In addition, the transportation mode of oil products is also directly related to the capacity of underground storage tanks. For example, oil transportation uses automobiles, and sufficient vehicle transportation conditions are guaranteed. Underground storage tanks may be smaller, and vice versa. It is emphasized here that gas stations preferably have their own car transport equipment. If the unit does not have its own car and needs to rent another unit car to transport the oil, the tank at the gas station may be larger. The environmental constraints around the gas station are also important. If the constraints are good, the tank capacity can be larger. If the conditions are not good, it can be smaller. The capacity calculation of the underground storage tank of the gas station can be carried out as follows:

V=[(Gk)(1000a)]*1.2 (2-2)

The design capacity of the underground storage tank gasoline or diesel in the V-gas station;

G-average daily fueling amount, L;

K-reserve days, generally take 2-3 days;

The utilization factor of a-storage is generally 0.9 for gasoline and 0.85 for diesel.

According to the above formula, the reasonable gas station capacity can be designed to ensure the stability of the fueling business and avoid the shortage of oil in the gas station. In short, the tank capacity of the gas station must meet the requirements of the vehicle that transports the oil to discharge the oil into the tank in time. Make sure there is enough oil to refuel the vehicle before the next oil.

The number of tanks is determined, and the total capacity of the underground tanks of the gas station and the capacity of the single tank can be determined according to the grade of the gas station. The calculation capacity of formula (2-2) is only the storage of one type of oil. For gas stations operating a variety of oils, it must be calculated according to different oils, but at least one tank is required for each type of oil. . Under a certain volume, it is more economical to select one tank than to select two or more tanks. The unit uses less steel and the floor space is correspondingly reduced. In the design, the comparison and selection of the scheme should be carried out, so that the gas tank storage tank setting can meet the needs of adding 3B without causing waste.

4. Tanker suction height

The vertical distance between the bottom of the underground tank and the oil pump unit of the tanker is called the suction height. The suction height of the domestic fuel dispenser is 3m, and the suction height of the imported fuel dispenser is 4m. Exceeding this range, the working performance of the tanker will be affected, so that the oil cannot be sucked up from the tank to the ground for refueling. The attraction height is related to factors such as the type, specific gravity, dynamic viscosity of the oil and the performance of the tanker. It is also related to the diameter and length of the pipeline, valves on the pipeline, elbows and other factors.

Sixth, gas station construction and construction procedures

The construction of the gas station is based on the design of the gas station and is based on the completion of the approval of the gas station. The following is a brief description of the general process of gas station construction from three stages: construction preparation, engineering construction and project acceptance.

1. Preparation for construction

In the preliminary preparation stage of gas station construction, there are three main tasks.

(1) Obtain the licenses and permits necessary for the construction. That is to say, the approval documents for the construction of gas stations issued by the provincial and district-level economic and trade departments, as well as the “Construction Land Planning Permit”, “Construction Engineering Planning Permit” and “Construction Engineering Start Permit”.

(2) Carry out bidding for the project, determine the construction unit, sign a detailed and comprehensive project contract with the construction unit, and prepare the construction plan for the construction unit.

(3) According to the contract, the self-water collection, municipal power supply, postal communication, sewage discharge, and site leveling of the construction site shall be connected, that is, the “five connections and one leveling project”.

2. Engineering construction

The construction of gas stations mainly includes main construction, technology, packaging, fire protection, lightning protection, anti-static, electromechanical, water supply and drainage, sewage, heating, environmental protection, greening and so on. In the specific construction process, we should pay attention to the following points:

(1) Strictly follow the design drawings to ensure the quality of the project. In the construction process, the prevention-oriented principle is adopted. Only the previous process can pass the acceptance test before entering the next process. Only the concealed project can pass the acceptance before entering the next process.

(2) Minimize construction time and save investment. Shortening the construction period is one of the measures to reduce development costs and increase profits. When signing a construction contract, the construction period should be linked to economic benefits. The construction unit shall control the overall cost of the project from three aspects: controlling the construction budget, project payment, and construction related costs, and saving investment.

(3) Pay attention to safety management and construction site management during construction. The construction unit shall dispatch engineering supervision to the construction site to supervise the whole process of construction.

(4) The fire protection, lightning protection, anti-static, environmental protection, etc. of gas stations should follow the principle of “simultaneous design, simultaneous construction, and same acceptance”.

3. Engineering acceptance

Project acceptance can be divided into two stages: preliminary acceptance and completion acceptance. The preliminary acceptance shall be carried out by the construction unit in the construction, design, use and other relevant units, and the completion acceptance shall be organized by the relevant government departments. The main contents of the project acceptance include: concealed project acceptance, single-top project completion acceptance, drawing data collation, delivery acceptance, project completion drawing, economic benefit and quality review.